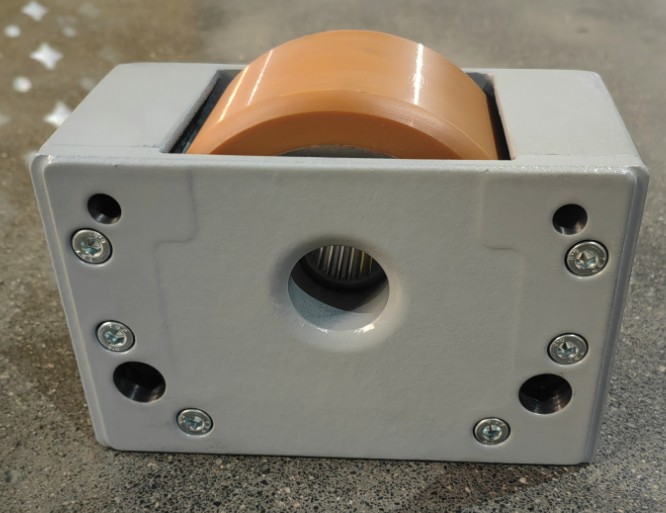

Warehouse Stacker Drive Wheels

The stacker crane drive wheels adopt high-wear-resistant wheel core with polyurethane coating, offering high load capacity and low noise performance, suitable for the travel systems of stacker cranes.

The warehouse stacker drive wheels are key drive component specially designed for the stacker, responsible for supporting and driving the stacker to move smoothly on the track. The drive wheels are usually coated with high-strength, wear-resistant polyurethane material, with good grip and low noise performance, and suitable for high-frequency handling environments such as warehousing and logistics. The drive wheels use a precise control system to achieve efficient advancement, stopping and positioning of the stacker on the track, ensuring that materials can be accurately stacked and improving the operating efficiency of warehouse automation.

Production process of stacker drive wheels

Raw material selection and preparation: Select high-quality metal materials (such as steel or aluminum) as wheel core materials, and polyurethane as rubber coating materials to ensure the strength, wear resistance and impact resistance of the wheel.

Wheel core processing: The wheel core is precisely processed by cutting, turning, drilling, etc. to ensure that it reaches the required shape, size and surface finish so as to better combine with the rubber coating material.

Pre-treatment of rubber coating: Clean and polish the surface of the wheel core, and perform special coating treatment to increase the adhesion of the rubber coating and ensure that the polyurethane or rubber adheres firmly to the surface of the wheel core.

Injection molding: Inject the polyurethane raw material into the mold for molding, and combine it with the wheel core through high temperature and high pressure to form a uniform and dense coating.

Curing and cooling: After molding, the drive wheels are placed in a curing oven to ensure that the material is stably cured to improve durability, and then slowly cooled under specific conditions to prevent deformation.

Precision machining: The cooled drive wheel is turned, polished and other processes to ensure the surface finish and the accuracy of the wheel outer diameter to meet strict dimensional tolerance requirements.

Inspection and quality control: Each drive wheel must undergo strict quality inspections before leaving the factory, such as wear resistance tests, dimensional inspections and load capacity tests, to ensure that its performance meets industrial requirements.

Features of stacker drive wheels

Made of high-quality polyurethane materials, excellent wear resistance and suitable for frequently used industrial environments.

The drive wheels material and design provide good grip to ensure smooth driving and precise positioning in various environments.

The material is corrosion-resistant and oil-resistant, suitable for industrial environments with high humidity and possible contact with chemicals.

Customized according to different equipment and load requirements, wide range of applications and meets the needs of various industrial equipment such as stackers, monorail cranes and automated guided vehicles.

The design is simple, durable, easy to maintain and replace, helping companies reduce operating and maintenance costs.

KUNFENG is committed to providing high-quality drive wheel solutions to customers around the world, focusing on meeting the high standards of drive systems for various industrial equipment. Our drive wheels products are made of advanced technology and high-quality materials, with excellent wear resistance, precise grip, and excellent anti-vibration and noise reduction performance. Click to contact us and get a free customized design solution and quote!

You Might Also Be Interested In: Crane Drive Wheel Block

Prev: none!!