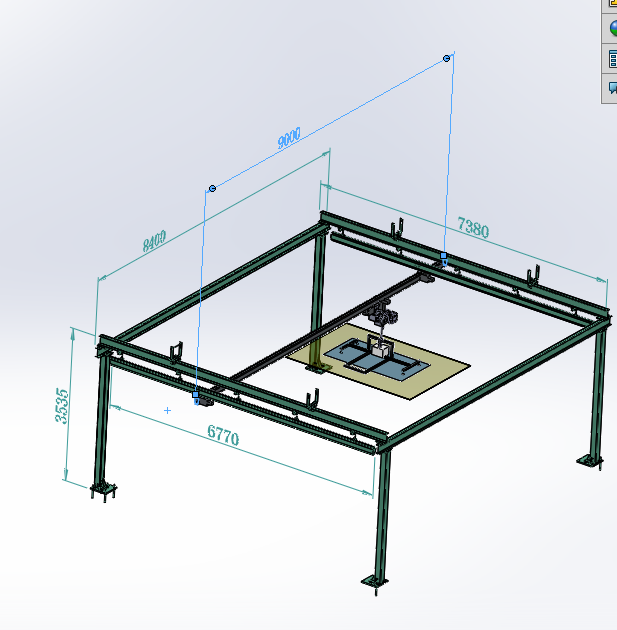

KBK Light Rail Workstation Crane System

The KBK light workstation crane system adopts modular rails and flexible suspension methods, featuring quick deployment and space-saving benefits, suitable for precision assembly lines and clean environments.

The KBK light rail workstation crane system is a modular, flexible and efficient material handling solution designed for fine work scenarios such as assembly lines, warehouses and clean workshops. It uses light rails as guides, combined with electric or manual hoists, trolleys and various hoists to achieve flexible lifting in the horizontal and vertical directions, provide continuous and efficient material handling for production lines in limited space.

Design Features of KBK Light Workstation Crane

Consist of standardized components such as rails, beams, connectors, hoists and trolleys, which can be freely combined according to site requirements to meet various spans and layouts.

The KBK system is lighter and does not require complex foundation construction. It can be directly installed on the steel structure or concrete support of the factory.

The system is equipped with low-friction rails and high-quality walking mechanisms to ensure smooth operation without jamming, suitable for scenarios with high positioning accuracy requirements.

No welding or punching, snap-on or bolt-type installation, can be quickly deployed and disassembled, shortening the project cycle.

Supports manual chain hoist, electric chain hoist and belt hoist, with electric or manual drive of trolley to meet different operation rhythms.

Equipped with overload protection, upper and lower limit, travel buffer and anti-drop device to ensure the safety of operators and equipment.

Technical Parameters (For Reference)

Rated load: 50kg ~ 2000kg

Horizontal span: 2m ~ 8m (customizable)

Lifting height: 1m ~ 6m (customizable)

Track material: carbon steel / aluminum alloy profile

Drive mode: manual / electric

Installation method: suspension / column support / ceiling installation

Operation control: hand-pull operation / button control / remote control

Typical Application Scenarios

Automobile manufacturing: Engine assembly, body welding line material transportation

Electronic industry: Precision parts handling, production line loading and unloading

Warehousing and logistics: Light cargo lifting, packaging line auxiliary operations

Mechanical processing: Mold replacement, small equipment relocation

Laboratory and R&D: Support repeated experiments and sample handling

We can provide personalized services such as track layout design, load optimization, electric / manual drive solutions according to your specific needs. Welcome to contact our technical team for detailed technical solutions and customized quotes!